Product Review: Regatta Men’s Navigate Hybrid Jacket

A couple of weekends ago (26th February 2023), I visited the Printwear and Promotion 2023 exhibition with Stuart at the NEC in Birmingham. Printwear and Promotion is one of the first exhibitions I’ve attended in a long while. While I was still determining what to expect in this post-Covid world, I was pleasantly surprised by the number of exhibitors, interactive workshops, and friendly approach towards someone who doesn’t specialise in the sector.

If you’re unaware, the Printware and Promotion exhibition allows the print industry access to the latest products and tech across the spectrum of garment and apparel printing. – Anything from hoodies and T-Shirts to Bags, Mugs, Keyrings & Pens.

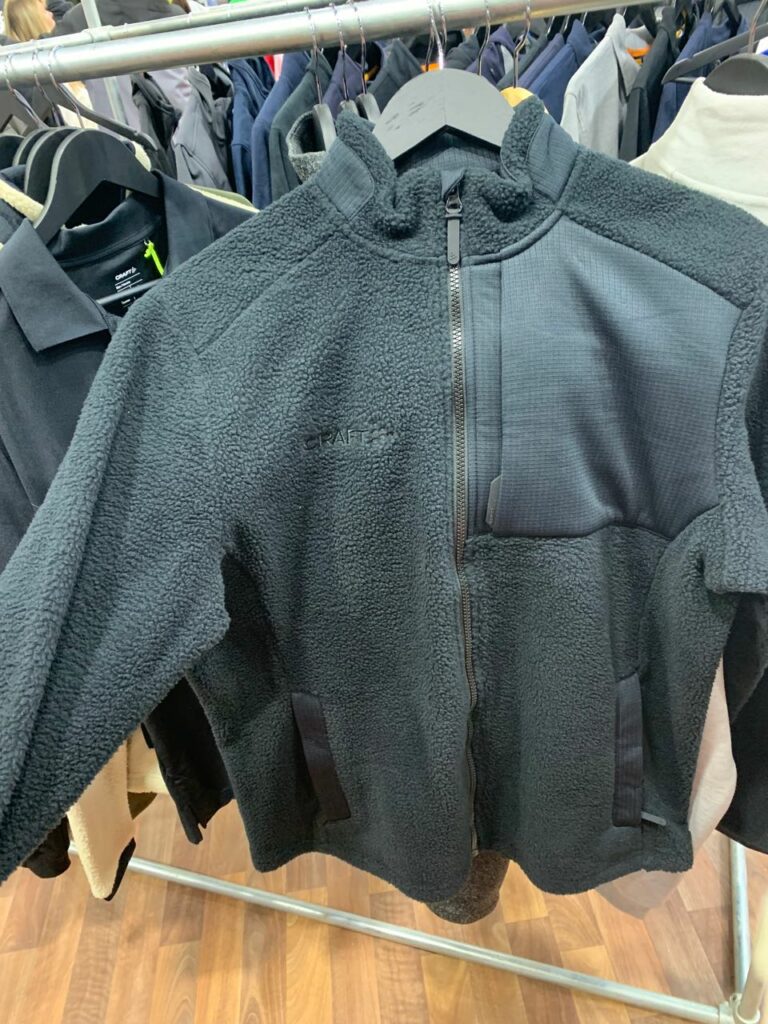

I’d, however, describe it as my other half’s nightmare. An exhibition hall full of clothing and shoes with no possibility of buying any of them. I still don’t think she’d have recovered now if she’d visited with us. However, a few suppliers were offering sample stock, and, more excitingly, Regatta allowed visitors to win some of their products. I’m always up for excitement like this, and never more than when it involves a “seaside” style grabber machine – a quick go, and on the first attempt, grabbing a bottle with a piece of paper. A quick trip to the desk revealed I’d won their top prize, the Men’s Navigate Hybrid Jacket. Excitement was at a fever pitch!

A few weeks later, I’ve been wearing the Regatta Navigate Hybrid Jacket on and off, and I’ve got to say, I’m impressed. I know a name like Regatta has high expectations in the clothing spectrum, especially for their outdoor kit. However, this lightweight jacket punches well above my expectation for such a light garment.

The jacket features Regatta’s Extol Stretch Technology which, in their words, is an “Ergonomic and flexible fabric for high energy activities”, and I can’t disagree. This fabric on the sleeves and hood provides enough warmth, but also freedom, and movement. The main body comprises Polyamide panels, which add a little more warmth but are also perfect for a small company, club or society logo on the chest.

The Regatta Men’s Navigate Hybrid Jacket features two lower pockets and a chest pocket, all ample for your day-to-day needs and truly is a jacket you can wear all day without feeling it. I’ve been surprised a couple of times by how light yet warm the sleeves are, and Regatta’s Extol Stretch Technology does seem to work well.

I’ve yet to find many negitive points, if any, to be honest. I’d say the size is a little “regatta” and you may find yourself needing to “size up”, but for a lightweight, day-to-day jacket, you can’t go wrong with Regatta’s Men’s Navigate Hybrid Jacket.